CONCENTRATION TO INNOVATION FOR REVOLUTION

NanoFiltech focus on the R&D, manufacture and sales of high-class functional nanofiber materials.

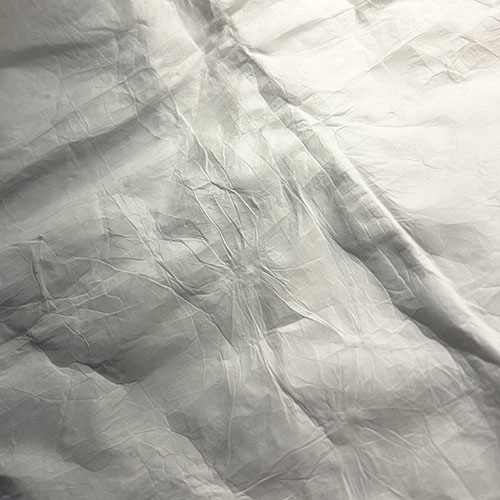

Flexible ceramic nanofiber membrane is an inorganic material, with lightweight, low thermal conductivity, high temperature resistance, corrosion resistance, long service life, and other excellent performance.

It is widely used in individual protection, aerospace, new energy vehicles, lithium-ion batteries, industrial high temperature pipelines and many other industries.

NANOFILTECH NANOFIBER CERAMIC INSULATION MATERIAL

INTRODUCTION OF COMPETITIVE PRODUCT- AEROGEL FIBROFELT

Aerogel fibrofelt which is filled with aerogel powder is the top high temperature insulation material in the world. It is widely used in some of the high-end manufacturing. Aspen and Cabot are top companies in aerogel powder manufacturing industry.

|

COMPANY |

PRODUCT |

THICKNESS (mm) |

DENSITY (kg/m3) |

HEAT CONDUCTIVITY COEFFICIENT (W/m·K) |

OPERATION TEMPERATURE (℃) |

PRICE ($/㎡) |

|

Aspen |

Pyrogel-XTE |

5-30 |

80-200 |

0.019~0.020 |

650 |

21.4-86 |

|

JIOS |

Armagell |

5~20 |

160~240 |

0.019~0.020 |

650 |

18.6-83 |

|

Cabot |

Opacified Infill |

5-30 |

70-200 |

0.019~0.020 |

650 |

21.4-129 |

|

Active Aerogel |

Aeroflex |

/ |

100~260 |

0.019~0.020 |

650 |

17.2-72 |

|

NanoFiltech |

NFC025 |

0.5~30 |

50~100 |

0.03~0.032 |

1100 |

10-29 |

COMPARASION WITH OTHER HEAT INSULATION MATERIAL IN THE MARKET

| PRODUCT NAME | ADVANTAGE | DISADVANTAGE |

|

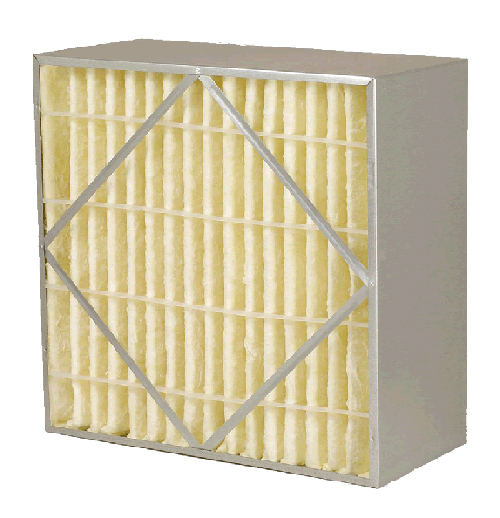

SUPER FINE FIBERGLASS WOOL |

Light weight, low thermal conductivity, good thermal insulation and sound absorption performance, corrosion resistance, heat resistance, frost resistance, earthquake resistance, high moth resistance, good chemical stability; |

Easy to damage, need to add protective layer; The fibers fall off easily and irritate the skin, eyes and respiratory tract. |

|

HIGH SILICA COTTON |

Low thermal conductivity; good thermal stability, chemical stability and sound absorption; non-corrosive substance. |

Poor compression and folding resistance, easy to generate the dust. |

|

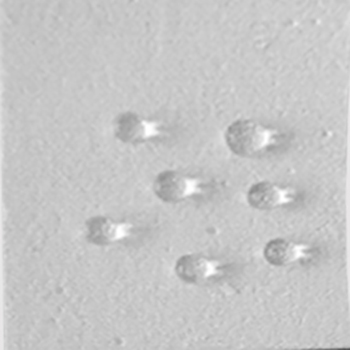

VACUUM INSULATION PANEL |

Low thermal conductivity, down to 0.004W(m·K) at room temperature; thin thickness, less volume, light weight |

The core material cannot be compressed as a whole in a vacuum environment; if the vacuum leaks, the thermal conductivity would increases instantaneously. |

|

FILTROFELT FILLED WITH AEROGEL POWDER |

Filled with aerogel powder, low thermal conductivity, excellent thermal insulation performance; good high-temperature resistance(up to 650℃) |

High brittleness, poor bendability; the powder is easy to fall off in dynamic conditions; needs to be combined with other materials; high material cost; can not be used in the environment above 650℃. |

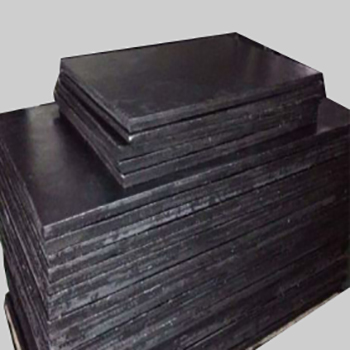

| POLYFOAM |

Low density, light weight, high specific strength. It has the ability to absorb shock load, has excellent cushioning and damping performance, low thermal conductivity, good thermal insulation performance, and its strength increases with the increase of density. |

Can not be compared with solid plastics in tensile strength; chemical stability and aging properties are related to the material. |

|

NANOFIBER CERAMIC MEMBRANE |

Low thermal conductivity, good heat insulation effect; the same insulation effect, thinner thickness and lighter weight than other materials; stable performance; good fire resistance; good plasticity; good impact resistance; the composition is inorganic material with long service life. |

/ |

TDS OF FLEXIBLE CERAMIC THERMAL INSULATION MEMBRANE

| Item | Unit | Testing result |

| Testing material | / | SiO2 |

| Thickness | mm | 0.5-30 |

| Density | Kg/m3 | 50-100 |

| Heat conductivity coefficient | W/mk | ≤0.032 |

| Operation temperature | ℃ | -200~1100℃ |

| Flame retardant performance | / | UL94V0 |

APPLICATIONS

HOT SALE