CONCENTRATION TO INNOVATION FOR REVOLUTION

NanoFiltech focus on the R&D, manufacture and sales of high-class functional nanofiber materials.

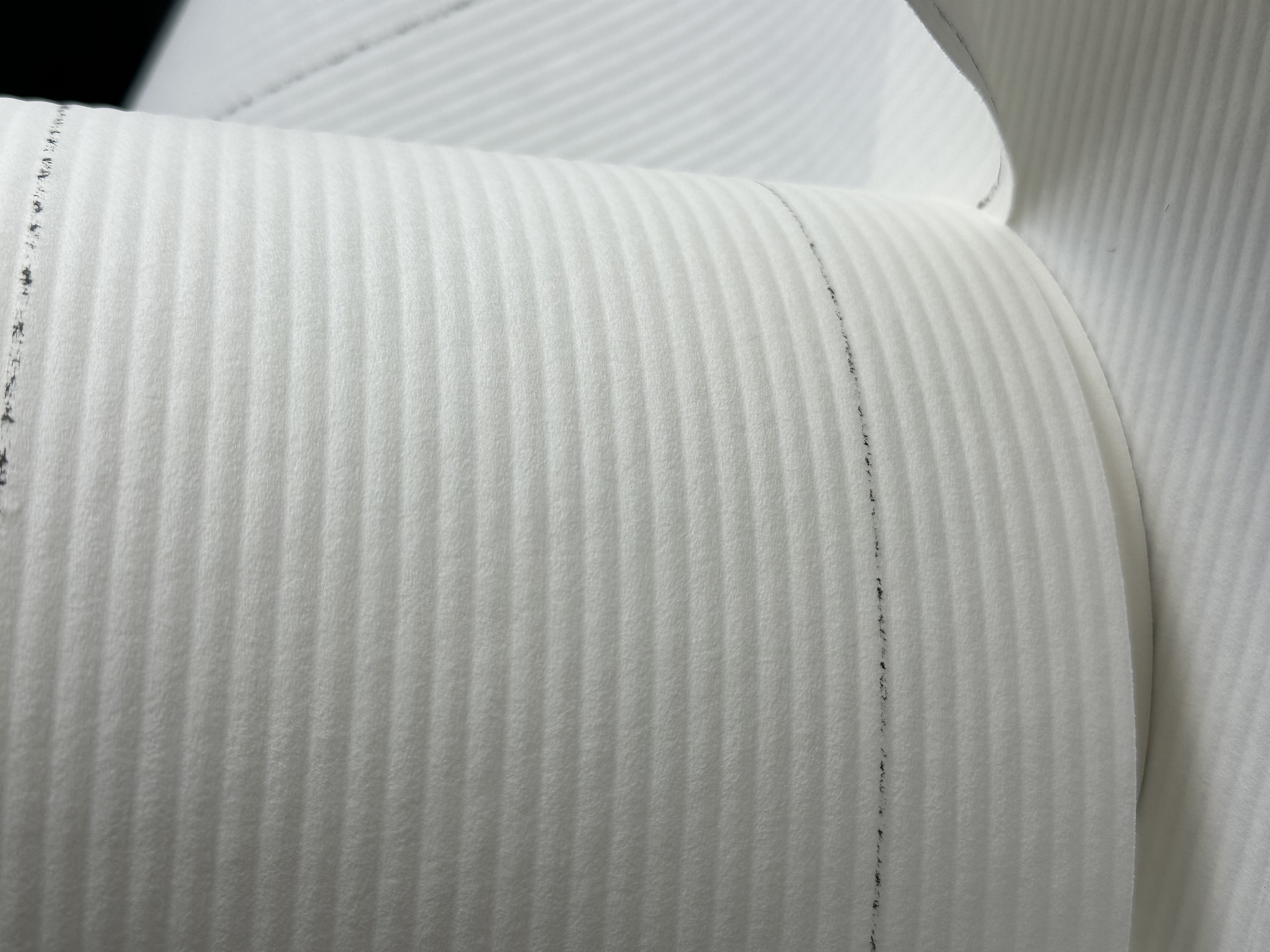

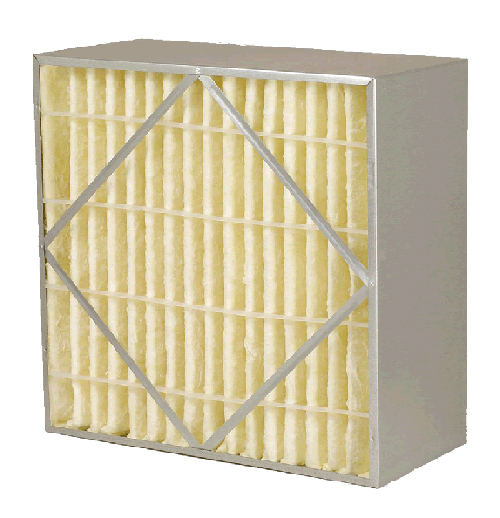

Our independently R&D electrospinning nanofiber coating technology offers greater flexibility, controllability and durability. We composite a nanofiber film on a base-material including, but not limited to, wood pulp paper to make traditional filtration materials more powerful performance. Nanofiber diameter of this product is usually 300nm-500nm, and the maximum size is 1 micron. It is mainly used in heavy air filtration equipments and industrial dust removal.

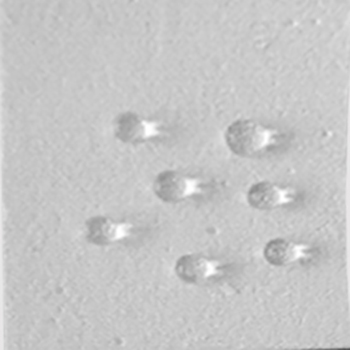

■ Nanofiber-coated wood pulp paper, water-proof, easy for blowback;

■ High filtration precision, high filtration efficiency, low pressure drop;

■ High dust holding capacity, no curing required, flame retardant and antistatic functions can be added;

■ Nanofiber diameter down to 80 nm;

WHAT IS IT?

TDS OF INDUSTRIAL NANOFIBER FILTRATION PAPER(for engine/turbine engine)

|

Product name |

Weight (g/m2) |

Total Thickness (mm) |

Corrugation Depth (mm) |

Max aperture size (μm) |

Stiffness (mN•m) |

Burst Strength (kPa) |

Dry MD Tensile Strength (N/15mm) |

Dry CD Tensile Strength (N/15mm) |

Air permeability@ △P=200Pa (L/ m2•s) |

Filtration Efficiency (%) |

Resistance (Pa) |

|

NFP70 |

120 ± 6 |

0.5±0.1 |

0.2±0.1 |

≤60 |

≥2.5 |

≥250 |

3.3 |

1.4 |

210±30 |

> 70 |

<50 |

|

NFP9570 |

125 ± 6 |

0.6±0.1 |

0.4±0.1 |

≤60 |

≥4.0 |

≥200 |

4.5 |

1.7 |

300±30 |

> 70 |

<50 |

|

NFP9570FR |

135 ± 6 |

0.45±0.05 |

0.2±0.1 |

≤60 |

≥4.0 |

≥200 |

3 |

1.7 |

310±30 |

> 70 |

<50 |

|

NFP9001FRA |

150 ± 7 |

0.6±0.1 |

0.35±0.1 |

≤70 |

≥3.0 |

≥200 |

3.5 |

1.7 |

250±30 |

> 70 |

<50 |

|

NFP90F9 |

95 ± 6 |

0.25±0.1 |

|

≤70 |

≥1.2 |

≥200 |

4.3 |

2.7 |

260±30 |

> 50 |

<65 |

|

NFP5045 |

120 ± 5 |

0.65±0.1 |

0.4±0.1 |

≤60 |

≥4.5 |

≥200 |

3.5 |

1.7 |

280±30 |

> 55 |

<50 |

TDS OF INDUSTRIAL NANOFIBER FILTRATION PAPER(for industrial dust filtration)

|

Product name |

Weight (g/m2) |

Total Thickness (mm) |

Corrugation Depth (mm) |

Max aperture size(μm) |

Stiffness (mN•m) |

Burst Strength (kPa) |

Dry MD Tensile Strength (N/15mm) |

Dry CD Tensile Strength (N/15mm) |

Air permeability@ △P=200Pa (L/ m2•s) |

Filtration Efficiency (%) |

Resistance (Pa) |

Surface electrical resistivity (Ω) |

Flame retardant level |

|

NFP7020 |

120 ± 6 |

0.6±0.1 |

0.3±0.1 |

≤60 |

≥3.0 |

≥350 |

3.3 |

1.4 |

210±30 |

> 70 |

<50 |

|

|

|

NFP900120FRA |

150 ± 7 |

0.65±0.1 |

0.35±0.1 |

≤70 |

≥3.5 |

≥300 |

3.5 |

1.7 |

180±30 |

> 70 |

<55 |

≤105 |

F1 |

|

NFP957020 |

120 ± 6 |

0.7±0.1 |

0.4±0.1 |

≤60 |

≥4.5 |

≥300 |

4.5 |

1.7 |

300±30 |

> 70 |

<50 |

|

|

|

NFP957020FRA |

135 ± 6 |

0.7±0.1 |

0.4±0.1 |

≤60 |

≥4.5 |

≥300 |

3 |

1.7 |

300±30 |

> 70 |

<50 |

|

F1 |

**Testing condition: Tested by Longman filtration inspection equipment; @wind 5.3cm/s,0.3 micron Nacl particles;

**Support layer can be customized by the customer. The test data will vary depending on the different support layer material;

Compared to the traditional cellculose filter media, industrial nanofiber filtration paper can provide higher filtration efficiency, higher air permeability, higher efficiency stability, higher lifespan, easier blowback, and energy cost saving.

APPLICATION

■ Woodworking: dust from grinding, polishing, sawing, milling, planing process;

■ Manufacturing: dust from crushing, mixing, feeding, bagging process;

■ Hardware: grinding, polishing, sawing, milling, planing process;

■ Food: dust generated during processing to the flour, rice, milk powder, grain and oil, etc.;

■ Chemical: fertilizer, paint, washing powder, dust generated by the production process;

■ Construction industry: dust from cement, ceramics, glass, fiber, steel, stone production process.

HOT SALE