CONCENTRATION TO INNOVATION FOR REVOLUTION

NanoFiltech focus on the R&D, manufacture and sales of high-class functional nanofiber materials.

■ Pure physical interception make it keeping high filtration efficiency without statics electrocity;

■ Large specific surface area make it keeping high dust holding capacity;

■ Thin fiber diameter(100nm-300nm) make it keeping very low pressure drop during operation;

■ Strong structure make it keeping high filtration efficiency from beginning to the end, 99.997% at most;

■ High dust holding capacity and high tensile strength make it longer lifespan;

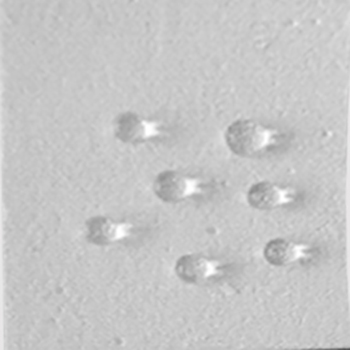

■ Small aperture and thin fiber make it keeping high hydrophobicity;

■ It is burnable;

MATERIALS COMPARASION

|

ITEM |

FIBERGLASS MEDIA |

NANOFIBER COMPOSITE MEDIA |

|

FIBER DIAMETER |

400-700nm |

100-200nm |

|

PHYSICAL INTERCEPTION EFFICIENVY |

>85% |

>85% |

|

AIR RESISTANCE |

83Pa |

36Pa |

|

AIR PERMEABILITY |

112.5L/ m2•s |

180L/m2•s |

|

LIFESPAN |

1 YEAR |

1 YEAR AND 4 MONTHS |

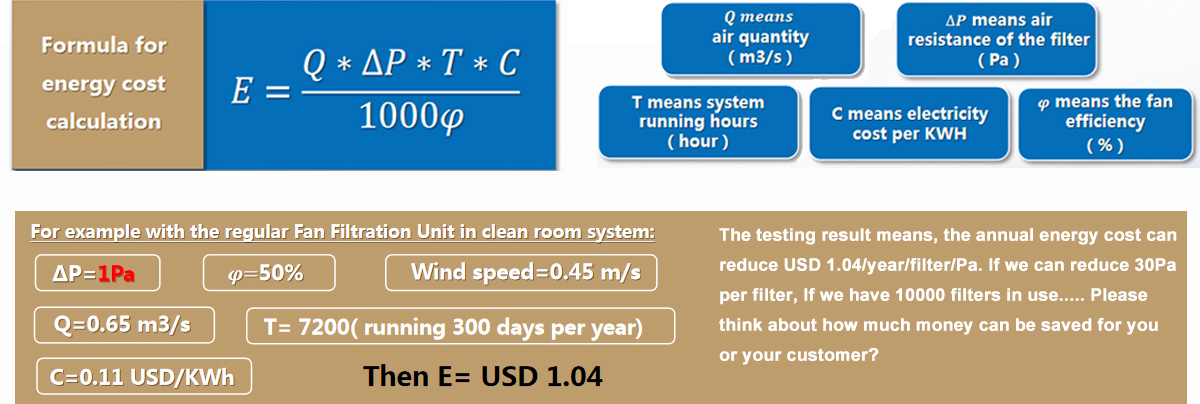

COST SAVING CALCULATION

TDS FOR NANOFIBER AIR FILTRATION MEDIA

| Filtration efficiency level | Unit | H9 | H9 | H10 | H10 | H11 | H11 | H12 | H13 | H14 | |

| Product name | / | NFTF9N | NFTF9HC | NFTH10N | NFTH10HC | NFTH11N | NFTH11HC | NFTH12 | NFTH13 | NFTH14 | |

| Weight (g/㎡) | / | 85±5 | 102±5 | 85±5 | 102±5 | 85±5 | 102±5 | 110±5 | 115±5 | 115±5 | |

| Thickness | mm | 0.6±0.05 | 0.65±0.05 | 0.6±0.05 | 0.65±0.05 | 0.6±0.05 | 0.65±0.05 | 0.65±0.05 | 0.65±0.05 | 0.65±0.05 | |

| Air permeability@200Pa | L/㎡.s | 350±20 | 350±20 | 300±20 | 300±20 | 260±20 | 260±20 | 100±10 | 55±10 | 45±10 | |

| Vertical Stiffness factor | mg | ≥400 | ≥450 | ≥400 | ≥450 | ≥400 | ≥450 | ≥500 | ≥500 | ≥500 | |

| Horizontal Stiffness factor | mg | ≥200 | ≥200 | ≥200 | ≥200 | ≥200 | ≥200 | ≥300 | ≥300 | ≥300 | |

| Initial filtration efficiency | % | ≥90 | ≥90 | ≥95 | ≥95 | ≥99 | ≥99 | ≥99.9 | ≥99.99 | ≥99.999 | |

| Final filtration efficiency | % | ≥80 | ≥85 | ≥90 | ≥90 | ≥95 | ≥95 | ≥99.5 | ≥99.97 | ≥99.995 | |

| Resistance | Pa | <38 | <38 | <45 | <45 | <52 | <52 | <155 | <180 | <230 | |

| Tensile strength | Before stretch | N/5cm | 185 | 197 | 185 | 197 | 185 | 197 | 127 | 112 | 106 |

| After freeze 24 hours in -20℃ | N/5cm | 189 | 201 | 189 | 201 | 189 | 201 | 130 | 114 | 108 | |

| After thaw | N/5cm | 187 | 198 | 187 | 198 | 187 | 198 | 129 | 113 | 108 | |

| After 1 hour baking in 80℃ | N/5cm | 191 | 206 | 191 | 206 | 191 | 206 | 133 | 116 | 109 | |

| Heat resistance | ℃ | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | |

| Dust holding capacity @32L/min 0.3μm NaCl |

mg/㎡ |

>950 @120Pa |

>1160 @120Pa |

>800 @120Pa |

>960 @120Pa |

>600 @120Pa |

>720 @120Pa |

>2150 @320Pa |

>2800 @320Pa |

>4050 @460Pa |

|

| Hydrophobicity | resistance before moisture |

Pa | 35 | 36 | 41 | 42 | 50 | 50 | 152 | 180 | 230 |

| resistance after moisture |

Pa | 35 | 36 | 41 | 42 | 50 | 51 | 153 | 181 | 232 | |

| filtration efficiency before moisture |

% | 97.6 | 97.6 | 98.4 | 98.4 | 99.2 | 99.2 | 99.9 | 99.9 | 99.999 | |

| filtration efficiency after moisture |

% | 97.4 | 97.4 | 98 | 98 | 98.8 | 98.8 | 99.74 | 99.98 | 99.996 | |

| Width range | mm | ≤1600 | ≤1600 | ≤1600 | ≤1600 | ≤1600 | ≤1600 | ≤1600 | ≤1600 | ≤1600 | |

| Length range | m | ≤500 | ≤500 | ≤500 | ≤500 | ≤500 | ≤500 | ≤500 | ≤500 | ≤500 | |

REMARK

■ It is with the structure of SUPPORT LAYER+MELT-BLOWN LAYER+NANOFIBER LAYER+SPUNBOND LAYER;

■ All the data above are from the test using 0.3μm NaCl particle,testing air capacity is 32L/min; Testing initial resistance is 120 Pa(for H12& H13 are @320Pa; for H14 is @460Pa), testing equipment TSI3160. Given that the test condition will be different, so if you want to test our product, this remark will be helpful and referable.

■ Final filtration efficiency means the filtration efficiency under the double initial air resistance which test intial filtration efficiency.

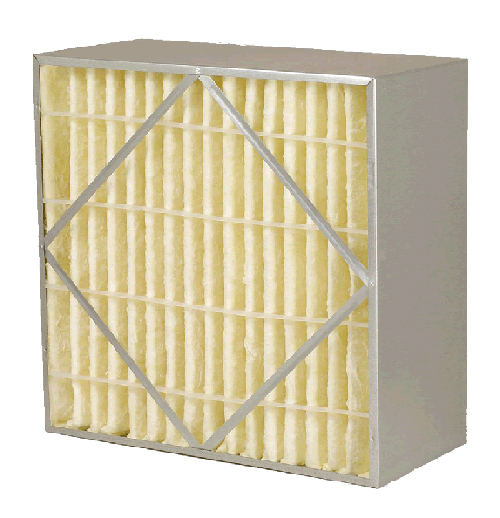

APPLIES TO THE HVAC SYSTEMS FOR FOLLOWING INDUSTRIES

HOT SALE