CONCENTRATION TO INNOVATION FOR REVOLUTION

NanoFiltech focus on the R&D, manufacture and sales of high-class functional nanofiber materials.

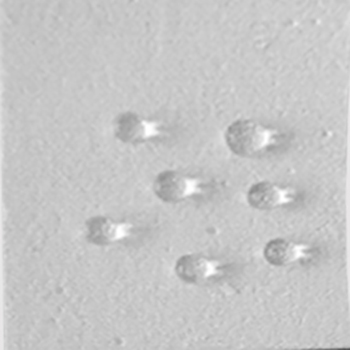

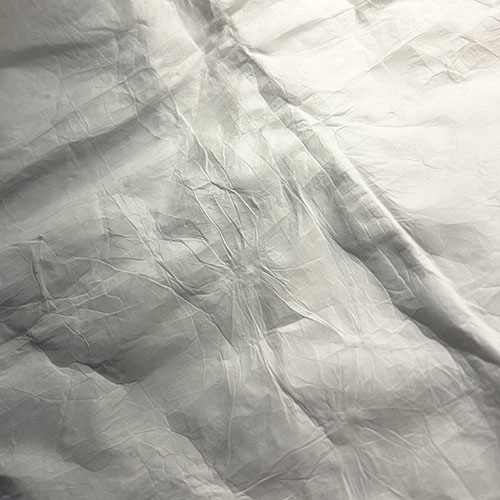

PTFE nanofiber membrane produced by bidirectional stretching process is a versatile high-end material with small and uniform aperture structure and high porosity (> 80%).

■ Super high filtration efficiency, our products covers H10-U16 level;

■ Its air resistance is only 1/2-1/3 of fiberglass material;

■ High chemical stability, high resistance to high temperature, corrosion and aging;

■ Low surface filtration performance, easy for blowback;

■ High acoustical and air permeability, and hydrophobicity;

■ Long lifespan with high tensile strength;

TDS FOR PTFE NANOFIBER COMPOSITE MEMBRANE

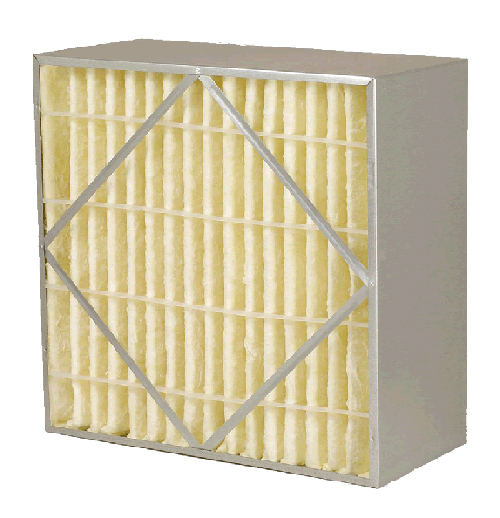

PTFE nanofiber composite membrane structure is SUPPORT LAYER+PTFE NANOFIBER MEMBRANE+SUPPORT LAYER. It can be applied to HEPA filter.

|

No. |

Filtration efficiency level |

Product name |

Weight (g/㎡) |

Thickness (mm) |

Filtration efficiency@TSI8130 32L/min NaCl (0.3μm) (%) |

Filtration efficiency@TSI8130 32L/min NaCl (0.1-0.2μm) (%) |

Resistance@TSI8 130 32L/min NaCl (Pa) |

|

1 |

ISO15E |

01690P230G80 |

80±5 |

0.3±0.05 |

≥99 |

≥95 |

60±20 |

|

2 |

ISO20E |

01290P80G80 |

80±5 |

0.3±0.05 |

≥99.5 |

≥99 |

80±20 |

|

3 |

ISO25E |

01295P95G80 |

80±5 |

0.3±0.05 |

≥99.9 |

≥99.5 |

95±20 |

|

4 |

ISO30E |

01390P105G80 |

80±5 |

0.3±0.05 |

≥99.95 |

≥99.9 |

105±30 |

|

5 |

ISO35H |

01395P120G80 |

80±5 |

0.3±0.05 |

≥99.995 |

≥99.95 |

120±30 |

|

6 |

ISO40H |

01490P135G80 |

80±5 |

0.3±0.05 |

≥99.995 |

≥99.99 |

135±30 |

|

7 |

ISO45H |

01495P150G80 |

80±5 |

0.3±0.05 |

≥99.999 |

≥99.995 |

150±30 |

|

8 |

ISO50U |

01590P165G80 |

80±5 |

0.3±0.05 |

/ |

≥99.999 |

165±30 |

|

9 |

ISO55U |

01595P220G80 |

80±5 |

0.3±0.05 |

/ |

≥99.9995 |

220±30 |

|

10 |

ISO60U |

01690P230G80 |

80±5 |

0.3±0.05 |

/ |

≥99.9999 |

230±30 |

|

11 |

ISO65U |

01695P250G80 |

80±5 |

0.3±0.05 |

/ |

≥99.99995 |

250±30 |

TDS FOR NONWOVEN FABRIC TECTORIAL PTFE MEMBRANE

PTFE nanofiber composite membrane structure is NONWOVEN FABRIC+PTFE NANOFIBER MEMBRANE. It can be applied to industrial dust collection sectors, etc.

|

No. |

Product name |

Thickness (mm) |

Weight (g/㎡) |

Thickness (mm) |

Resistance@TSI8130 32L/min NaCl (Pa) |

Filtration efficiency@TSI8130 32L/min NaCl (0.3μm) (%) |

Verticle tensile strength (N/5cm)

|

Horizontal tensile strength (N/5cm) |

|

1 |

JZ100H11 |

0.4±0.05 |

100±5 |

0.3±0.05 |

45±10 |

≥95 |

220 |

80 |

|

2 |

JZ100H12 |

0.45±0.05 |

100±5 |

0.3±0.05 |

120±20 |

≥99.5 |

300 |

80 |

|

3 |

JZ120H11 |

0.5±0.05 |

120±6 |

0.3±0.05 |

50±20 |

≥95 |

320 |

90 |

|

4 |

JZ120H12 |

0.5±0.05 |

120±6 |

0.3±0.05 |

120±20 |

≥99.5 |

320 |

90 |

|

5 |

JZ120H13 |

0.5±0.05 |

120±6 |

0.3±0.05 |

250±25 |

≥99.97 |

320 |

90 |

TDS FOR PET TECTORIAL PTFE MEMBRANE

PTFE nanofiber composite membrane structure is PET LAYER+PTFE NANOFIBER MEMBRANE. It can be applied to commercial& industrial dust collection sectors, etc.

|

No. |

Product name |

Filtration level |

Thickness (mm) |

Weight (g/㎡) |

Filtration efficiency@TSI8130 32L/min NaCl (0.3μm) (%) |

Verticle tensile strength (N/5cm)

|

Horizontal tensile strength (N/5cm) |

|

1 |

DP100H13 |

H13 |

0.38±0.05 |

100±5 |

≥99.97 |

300 |

260 |

|

2 |

DP100H14 |

H14 |

0.38±0.05 |

100±5 |

≥99.995 |

300 |

260 |

|

3 |

DP120H12 |

H12 |

0.4±0.05 |

120±6 |

≥99.5 |

350 |

280 |

|

4 |

DP150H11 |

H11 |

0.45±0.05 |

150±8 |

≥95 |

380 |

330 |

|

5 |

DP150H12 |

H12 |

0.45±0.05 |

150±8 |

≥99.5 |

380 |

330 |

|

6 |

DP150H13 |

H13 |

0.45±0.05 |

150±8 |

≥99.97 |

380 |

330 |

|

7 |

DP200H14 |

H14 |

0.48±0.05 |

200±10 |

≥99.995 |

700 |

600 |

|

8 |

DP130H14 |

H14 |

0.45±0.03 |

130±10 |

≥99.995 |

330 |

290 |

TDS FOR TWO-COMPONENT NONWOVEN FABRIC TECTORIAL PTFE MEMBRANE

PTFE nanofiber composite membrane structure is TWO-COMPONENT NONWOVEN FABRIC+PTFE NANOFIBER MEMBRANE. It can be applied to commercial& industrial dust collection sectors, etc.

|

No. |

Filtration efficiency level |

Thickness (mm) |

Weight (g/㎡) |

Resistance@TSI8130 32L/min NaCl (Pa) |

Air permeability @△P=200Pa (L/ m2•s)

|

Filtration efficiency@TSI8130 32L/min NaCl (0.3μm) (%) |

Verticle tensile strength (N/5cm) |

Horizontal tensile strength (N/5cm) |

|

1 |

DP130H13S |

0.38±0.05 |

130±7 |

350±35 |

|

≥99.95 |

450 |

270 |

|

2 |

DP240H11S |

0.6±0.05 |

240±12 |

150±15 |

|

≥95 |

720 |

600 |

|

3 |

DP240H12S |

0.6±0.05 |

240±12 |

200±20 |

|

≥99.5 |

720 |

600 |

|

4 |

DP240H13S |

0.6±0.05 |

240±12 |

350±35 |

>70 |

≥99.95 |

720 |

600 |

|

5 |

DP260H11S |

0.6±0.05 |

260±13 |

150±15 |

>70 |

≥95 |

930 |

800 |

|

6 |

DP260H13S |

0.6±0.05 |

260±13 |

350±35 |

|

≥99.95 |

930 |

800 |

|

7 |

DP170H11S |

0.5±0.05 |

170±10 |

80±16 |

|

≥95 |

580 |

430 |

APPLICATION

HOT SALE